Are you looking for better performance for your milling machine?

Do you want to reduce the contamination caused by the lubricant used in the bearings?

Do you have the goal of extending the life of your products and reducing maintenance intervals?

Is productivity improvement a must for your customers?

Lyra Bearing has a solution!

An experienced team of technicians, designers, materials engineers and specialists in the milling machine sector has studied and designed a line of super precision bearings that will meet all your needs and allow you to achieve results that were impossible until now.

Lyra's super precise bearings are:

Super precision lyra full ceramic

- Hole diameter 10–100 mm

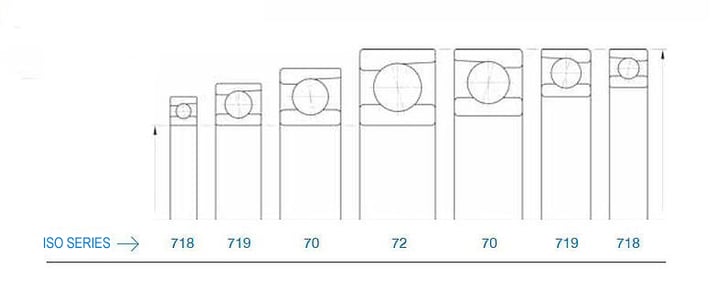

- Series iso 718,719, 70 and 72

- Nominal contact angle 15 ° –25 °

- Zirconium Oxide Rings

- Phenolic Resin Cages

- Silicon Nitride Spheres

- P4 Precision

- Optimization of internal geometries to reach the maximum number of revolutions

- Possibility to produce special dimensions

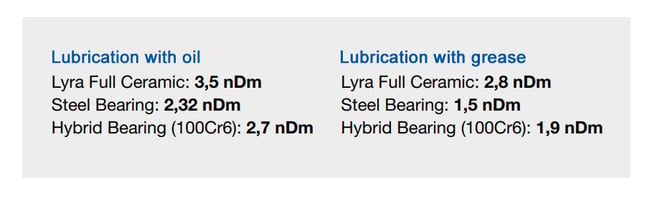

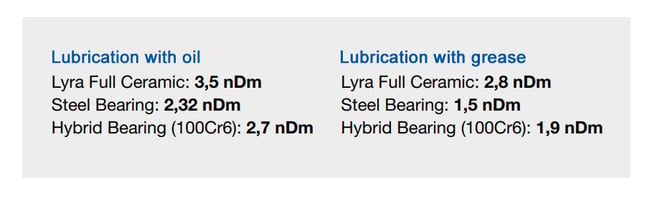

- Speed factor with oil lubrication 3.5 NdM Speed factor with grease lubrication 2.8 NdM

LYRA FULL CERAMIC BEARINGS IN THE ELECTRIC SPINDLE

What are the advantages for the electro-spindle with the use of Lyra Full Ceramic?

- Reduces or eliminates the use of lubricating oil

- Increased speed and performance

- Reduces the heat generated by the bearings

- Greater stability of the functional values of the bearing group (contact angles and preload values)

- Increased life of bearings operating in good conditions lubrication

- Greater stability of the elastohydrodynamic (EHL) condition even in conditions of poor lubrication.

- Reduces and / or eliminates the need for air-oil lubrication, facilitating compliance with workplace contamination regulations

MAIN FEATURES OF THE CERAMIC MATERIAL

- Thermal resistance

- Low coefficient of friction

- Chemical resistance

- Reduced weight compared to steel

- Reduced thermal expansion

- Non-magnetic

FULL CERAMIC BEARINGS BY LYRA BEARINGS

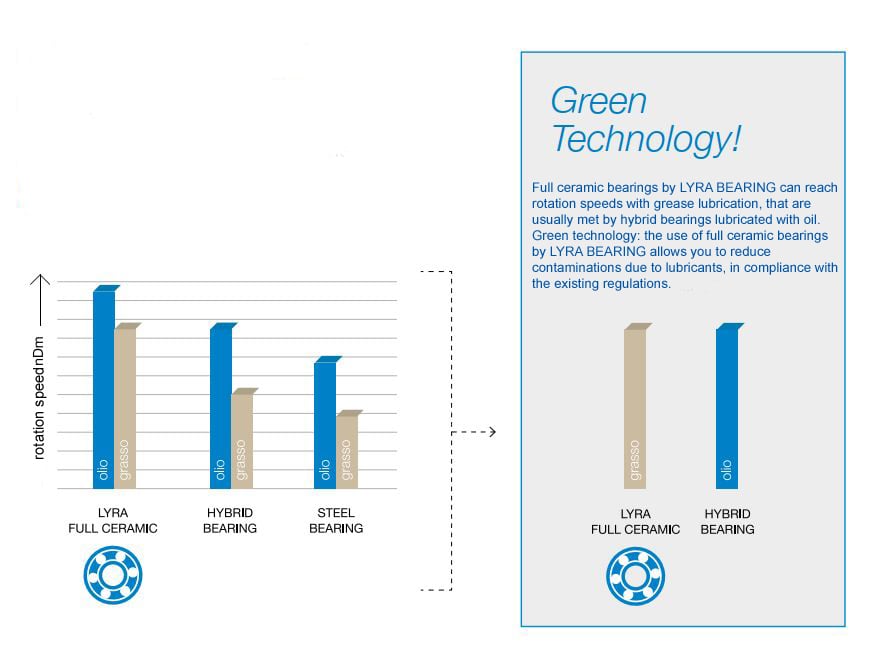

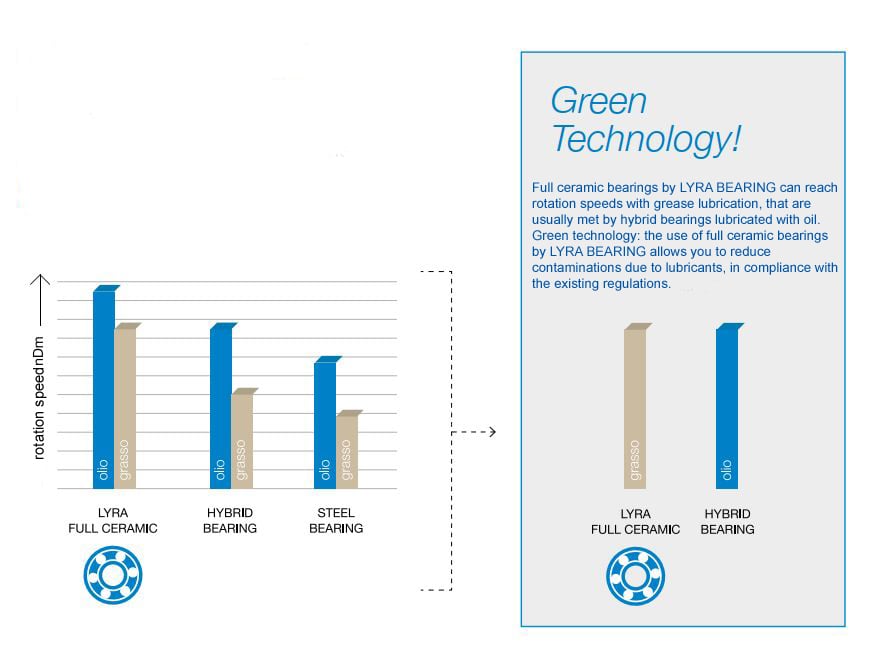

COMPARISON OF ROTATION SPEED BETWEEN SUPER PRECISION BEARINGS

Super precision lyra HYBRID

- Hole diameter 8–220 mm

- Series iso 718,719, 70 and 72

- Nominal contact angle 15 ° –25 °

- 100Cr6 Steel Rings

- Phenolic Resin Cages

- 100Cr6 Steel Balls Precision P4-P2

- Optimization of internal geometries to reach the maximum number of revolutions

- Possibility to produce special dimensions

- Speed factor with oil lubrication 2.6 NdM

- Speed factor with grease lubrication 1.7 NdM

- 2RZ version

- DL version Oil lubrication hole

Super precision lyra steel

- Hole diameter 8–460 mm

- Series iso 718,719, 70 and 72

- Nominal contact angle 15 ° –25 °

- 100Cr6 steel rings

- Phenolic resin cages

- 100Cr6 steel balls

- P4-P2 precision

- Optimization of internal geometries to reach the maximum number of revolutions

- Possibility to produce special dimensions Speed factor with oil lubrication 2,32 NdM

- Speed factor with grease lubrication 1,5 NdM

- 2RZ version DL version Oil lubrication hole

Lyra Bearing, offers a full range of super precision bearings, contact our team to find out more.