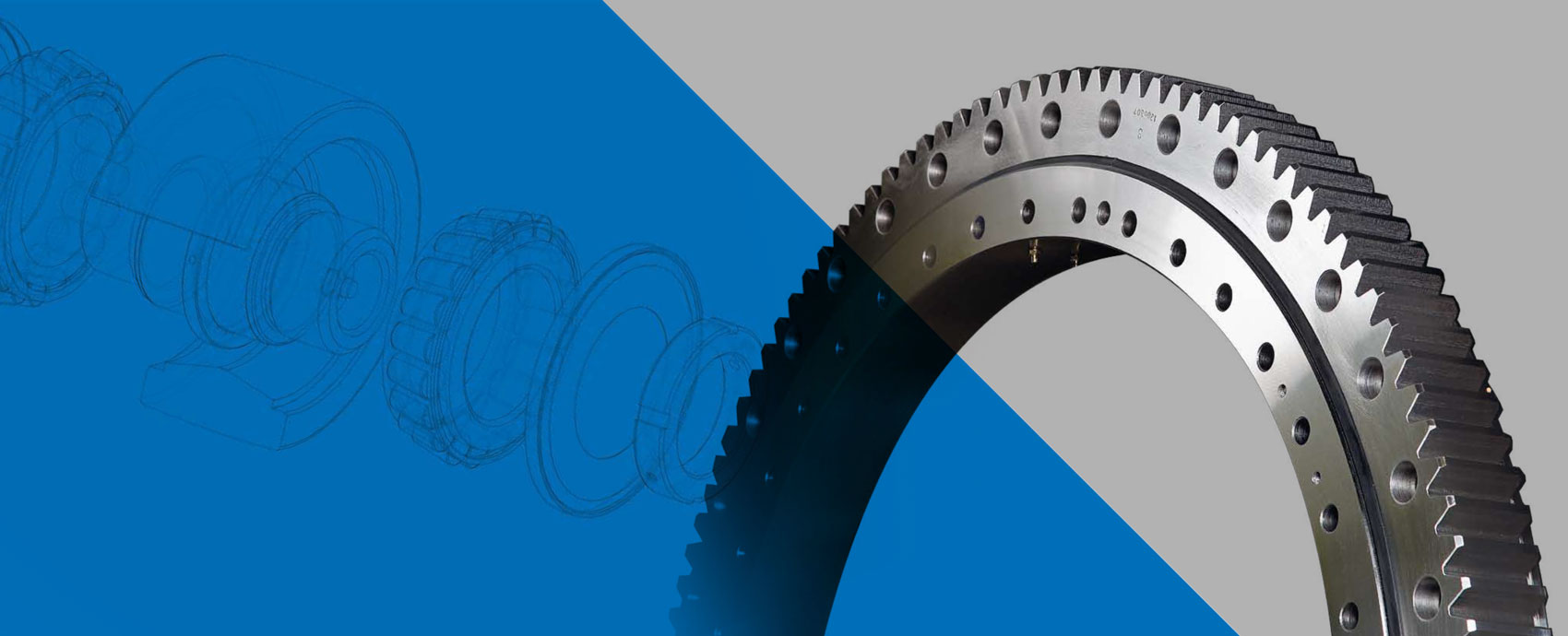

Base bearings or slewing bearings, as they are more commonly described, are used inside a machine or system when it is necessary to guide the rotary motion of one part in relation to another. A slewing bearing must guarantee support for the required loads with maximum rigidity within the precision range appropriate to the application, comply with operating parameters and offer a service lifetime compatible with the lifetime of the machinery to which it is fitted.

A slewing bearing consists of two steel rings enclosing:

Rings are mainly made of 50Mn carbon steel or alloy steels such as 42CrMo4 and the choice of material depends on the required mechanical properties. Alloy steels are often used for heavy-duty applications. Their structural characteristics mean that heat treatments are more effective and greater surface hardness can be obtained than with carbon steels. Stainless steels such as AISI420 or AISI440C can be used for applications where corrosion resistance is required.

The raceways are heat-treated by induction in order to achieve a maximum surface hardness of 62 HRC for carbon or alloy steels, or 58 HRC for stainless steels. The hardening depth can vary depending on the type of steel. Hardening treatment is essential to allow the slewing coupling to support the heavy-duty loads it is exposed to in its intended application.

The rotating elements used in slewing bearings may be balls or cylindrical rollers; both are typically made of 100Cr6 steel but other materials such as ceramic (zirconium oxide ZrO2 or silicon nitride Si3N4) or stainless steel (AISI440C) can be used. Rolling elements with different materials, sizes and precision grades are selected depending on the desired results.

Slewing bearing clearance plays a crucial role and is defined and optimised according to the application and performance to be achieved.

Cages or spacers made of different materials can be used to separate rolling elements, balls or rollers, depending on the loads and speeds required by the specific application.

Special sliding seals are fitted between the inner and outer ring to protect the slewing bearing against the ingress of debris, dust or water particles that could affect its operation. The material used for seals is typically NBR rubber, but different materials can be chosen for specific applications.

The lubricant is another very important factor to ensure effective operation of the base bearing. The type of lubricant, quantity, quality, lubrication intervals, number and position of greasing points are determined according to the performance required of the slewing bearing and any specific customer requirements.

Slewing bearing rings can be spur-gear or, more rarely, helical-gear. The gear module is sized and selected according to the application requirements.

Typically, the gearing is soft, i.e. untreated – the maximum hardness of untreated gears is 30 HRC for 42CrMo4. When service conditions require it, the gear surface can be induction-hardened to achieve a surface hardness of 60 HRC. Gear hardening is required when at least one of the following variables must be satisfied:

The experience gained by Lyra Bearing allows us to design slewing bearings to specific customer needs. You can get the right product for your machines or systems without having to compromise with an off-the-shelf product.