The life of the bearings of electric motors can be increased by at least four times when switching from normal steel bearings to ceramic bearings.

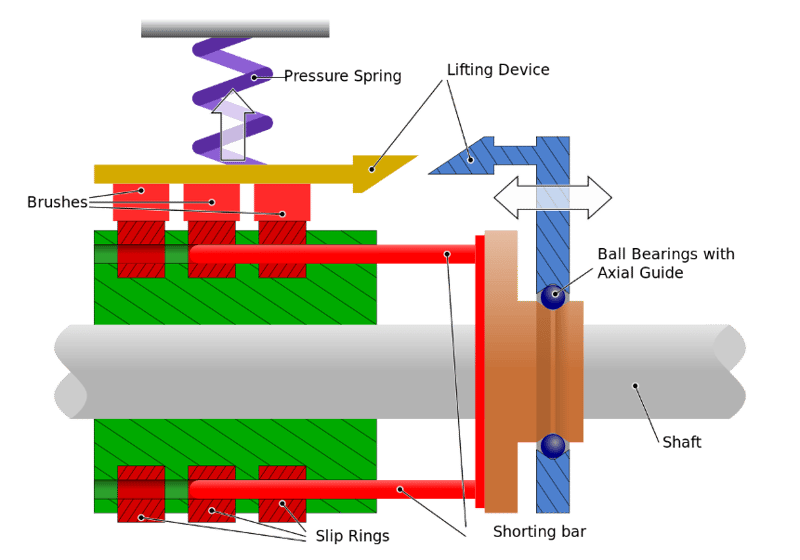

A problem commonly encountered in medium and large electric motors can be traced back to traditional standard ISO bearings due to parasitic currents generated by current converters (INVERTERs). Parasitic or carrier currents are usually the basis of most such concerns. Current erosion is the formation of microscopic welds in the path from the balls to the rolling track. This phenomenon can lead to reduced strength of the steel and erode the rolling track. Currently, this phenomenon, in the multiplicity of applications, finds its answer in bearings with a treatment of insulating material placed on the outer ring.

FULL CERAMIC bearings are indispensable for all those applications where only insulation

of the outer ring is not sufficient such as:

- high or very high operating temperatures;

- needs for greater silence / smoothness;

- extension of the life of the bearing;

- presence of aggressive vapors, acids or saline in addition to total electrical insulation.

The operation of ceramic bearings and the durability of lubricants

Unlike steel bearings, the high electrical resistance characteristic of hybrid or full ceramic ceramic bearings adequately insulates the entire diameter of the ball. This can be very effective compared to coating a bearing to offer electrical insulation. Predominantly, greased bearings are used for life, where the life is closely linked to the life of the lubricant rather than to the loads to which the bearings are subjected. You can use the number of operating parameters to approximate the service life of the grease, as well as the expected life of the greased bearing for life. These parameters to consider include the type of grease, size, speed and type of bearing and its operating temperature.

Using data from the graphical analysis of bearing and lubricant suppliers, it is possible to record the trend that the increase in bearing temperature by 15 degrees, compared to the reference temperature in continuous operation, will reduce the life of the grease by 50%.

For example, if the reference temperature in continuous operation is 80K, at 95 K, the lubricant will decrease by 50% of its effectiveness.

Clearly, working at temperatures lower than the reference temperature, prolongs, abundantly, the life of the bearing.

With the same operating conditions, the ceramic bearing, due to the smoothness and characteristic of the material that composes it, works at lower temperatures with all the benefits that follow.

In summary

In line with the relevant parameters to be considered to preserve the motors, ceramic bearings are superior to equivalent standard steel bearings. This is because they preserve the durability of the grease, bearing and engine due to reduced friction and high insulating properties.

We have explained to you only one of the many aspects that make this product the best ally of your machines. We have delved further into the advantages and operation of bearings in a dedicated guide that also contains possible applications.

As you can see, the choice of the best ceramic bearing in terms of mechanical resistance is also influenced by the selection of the ceramic component. Enter the world of bearings with our team to find the best solution for your applications.

Ceramic bearings for electric motors

07/07/2021 Posted in ceramic bearings, Industry from Francesco Madaro: R&D Manager, Ingegneria dei Materiali

“The study and development of materials for structural, electronic, energy and biomedical applications offer me every day the privilege of discovering little secrets of their behavior and adapting them to the applications in which they perform best. Ceramic materials are certainly my specialty, and ceramic bearings promise the most interesting performances in many applications ".