In this article we will talk about ceramic bearings or zirconia ceramic bearings with a special focus precisely in the material of these bearings.

If in the previous article we talked about the toughening of the ceramic bearing, in this we will focus on zirconia.

Toughened ceramics

Since the discovery and development of stabilized Zirconia in the 1960s, toughening by phase transformation (described in the previous article) was considered a property of partially stabilized zirconia (PSZ) with doping agents such as yttria, ceria, magnesia. To summarize, in the PSZ, the particles or grains of the tetragonal phase are homogeneously dispersed in the cubic phase. The tetragonal phase, metastable, i.e. unstable, transforms into a monoclinic phase in the phase of excessive mechanical stress, causing a phenomenon of toughening of the material.

Later, it was understood that this phenomenon could be replicated in other materials that had other materials such as alumina (aluminum oxide) as a matrix, in which zirconia particles are dispersed, which acts as a toughening agent. In other words, there is a whole family of ceramic materials that can be toughened with the help of the addition of zirconia particles, thanks to the phase transformation (tetragonalàmonocline) in the presence of thermo-mechanical stresses.

In the international technical-scientific community, these with zirconia toughened ceramic materials are known with the acronym ZTC (Zirconia Toughened Ceramics), that is, ceramic toughened with zirconia, or also called "ceramic steels".

However, the criticality of the preparation process lies in the ability to keep the Zirconia particles within a critical size, below which it is possible to keep the zirconia in the tetragonal metastable phase, which then, as described before, and in the previous article, in presence of a solicitation turns into monoclinic, triggering the toughening phenomenon.

Terminology of Zirconia

Specific terminology has been developed to describe stabilized zirconia and zirconia toughened ceramics.

A material with tetragonal phase particles in a cubic matrix is called partially toughened zirconia, or simply PSZ, to which a prefix of the element relating to the stabilizing agent is added (for example Ca-PSZ, stabilized with CaO, or Y-PSZ , stabilized with Y2O3, or Mg-PSZ, stabilized with MgO).

If we add enough stabilizer, the material will only contain cubic phase, and is referred to as fully stabilized zirconia or fully stabilized zirconia. Materials with only a tetragonal phase are indicated by the name of polycrystals in tetragonal zirconia.

Table 1 shows the codes of the different versions of ceramic toughened with zirconia.

Table 1. Abbreviations

|

Material |

Abbreviation |

|

Tetragonal zirconia polycrystalline |

TZP |

|

Partially stabilized zirconia |

PSZ |

|

Fully stabilized zirconia |

FSZ |

|

Ceramics toughened with zirconia |

TTC |

|

Alumina toughened with zirconia |

ZTA |

|

Zirconia toughened with phase transformation |

TTZ |

Each composition has its own characteristics, therefore it can be the most suitable solution for a specific application as summarized in Table 2 below.

Table 2. Material Properties.

|

Proprietà |

Y-TZP |

Ce-TZP |

ZTA |

Mg-PSZ |

3Y20A |

|

Density (g.cm-3) |

6.05 |

6.15 |

4.15 |

5.75 |

5.51 |

|

Hardness (HV30) |

1350 |

900 |

1600 |

1020 |

1470 |

|

Bending strength (MPa) |

1000 |

350 |

500 |

800 |

2400 |

|

Compression strength (MPa) |

2000 |

- |

- |

2000 |

- |

|

Young’s modulus (GPa) |

205 |

215 |

380 |

205 |

260 |

|

Poisson ratio |

0.3 |

- |

- |

0.23 |

- |

|

Fracture toughness (MPa.m-1/2) |

9.5 |

15 - 20 |

4 - 5 |

8 - 15 |

6 |

|

Thermal expansion coefficient (x10-6 °C-1) |

10 |

8 |

8 |

10 |

9.4 |

|

Thermal conductivity (W.m-1.K-1) |

2 |

2 |

23 |

1.8 |

3 |

To summarize, three families of ceramic materials toughened with zirconia can be distinguished thanks to the tetragonalàmonoclinic transformation:

- Toughened ceramic with dispersed particles

Materials in which a percentage (approx. 15%) of zirconia is added to a matrix (for example alumina, ZTA). In this case the stabilization of the tetragonal phase does not take place with doping agents such as Yttria, or Calcia, but with a heat treatment and with a dimensional control of the zirconia particles. The thermal treatment causes the tetragonal phase to remain at room temperature, forcing the particles not to transform into a monoclinic due to dimensional impediments. The tetragonalàmonoclinic transformation obviously will need to happen when the material is subjected to mechanical stress during use. This behavior recalls the heat treatments and transformations of martensite in steels.

- Partially stabilized zirconia

Zirconia doped or stabilized with agents such as yttrium oxide, calcium, magnesium, cerium. The doping agent promotes the stabilization of the tetragonal phase, responsible for the toughness of the material. Generally we have a cubic phase matrix, with an unstable tetragonal phase percentage.

- Fully tetragonal polycrystalline zirconia

In the 1970s it was reported that grains smaller than half a micron with very low concentrations of Yttria stabilizer, could generate materials in which the stabilized tetragonal phase was 98% higher. To ensure the benefits of toughening, it is essential that the grain size does not exceed 0.3 microns.

Lately, another family of toughened zirconia-based ceramic materials is gaining momentum: the so-called nanomaterials, in which it is important to keep the grain size below 110 nm, in order to have mechanical properties, such as toughness at fractures that exceed the current performance of existing materials.

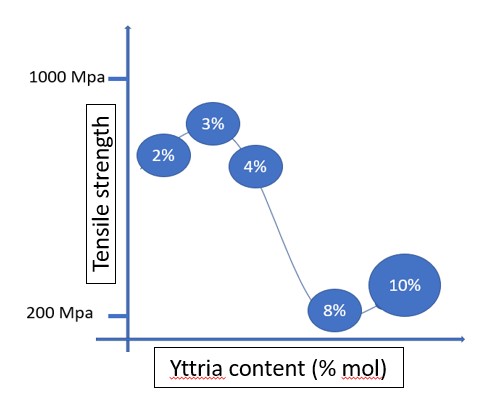

Tensile strength of zirconia as the yttria content varies.

A fundamental aspect in the use of ceramic materials is their limited tensile strength. When a bearing is fitted on a rotating axis, it will undergo thermal expansion of the same, bringing it to traction, which if it exceeds the myths of the materials, will cause it to break.

The tensile strength as the amount of yttria of zirconia varies has a trend similar to the graph shown in Figure 1, with a maximum around the value of 3% mol (content in mol%), and tensile strength values between 600 and 800 Mpa.

Figure 1. Tensile strength of stabilized Zirconia as a function of Yttria content.

Bearings in zirconium oxide

The following are the basic properties of zirconium oxide bearings

- Electrical insulation

- Low thermal conductivity

- High resistance to corrosion and acids, with the exception of HF acids

- Medium friction (HV> 1400)

- Without cage: «full complement»: 500 ° C

- With PEEK cage: 300 ° C

- With PTFE cage: 250 ° C.

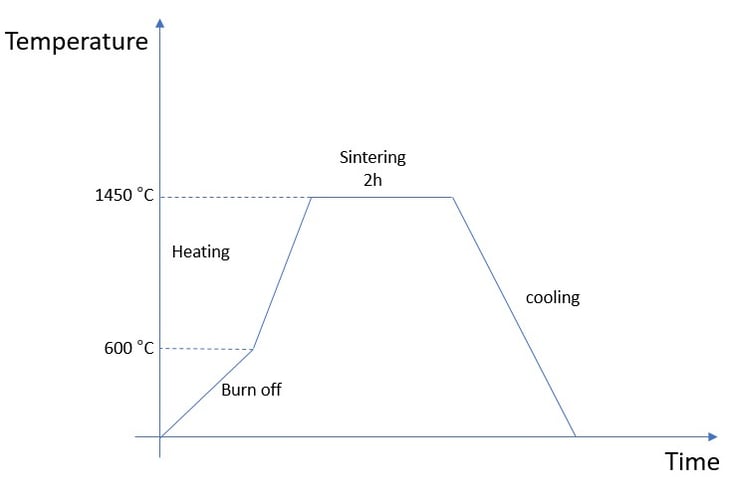

Figure 2 shows a typical sintering program of a Zirconia product. After a first slower heating ramp for the combustion of any organic products, the optimal sintering temperature is reached, and then controlled cooling is carried out up to room temperature.

Figura 2. Sintering program for Zirconia

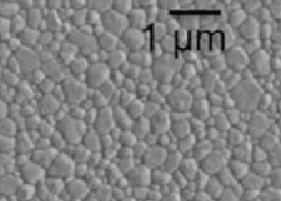

Sintering or firing causes the powder particles to undergo a transformation of their conformation to the solid state, without melting. The atomic migration activated by the temperature, allows the particles to form connecting regions which then swell up to form a structure in which the voids (pores) between the particles are eliminated, obtaining a very high density structure.

Figure 3 depicts a part of a Zirconia component after sintering. The conformation of the ceramic can be observed at a microscopic level, with the grains and their separation regions (grain boundaries).

Figura 3. Micrograph of a sintered Zirconia component.

The choice of the best components passes through in-depth knowledge of the materials! Put yourself in the hands of our bearing experts to make the best choice for your application.