The choice of a material for a component for engineering applications such as bearings is dictated by several factors and not just by the characteristics of the material.

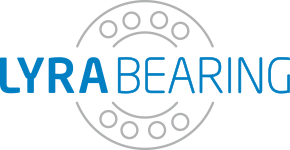

It is necessary to consider the limits imposed by the bearing shape and cost, as well as by the distribution of loads and stresses, tolerances and other boundary conditions such as:

Operating conditions are not the only factors to be taken into consideration since ceramic materials also need particular attention during their manufacture, both in the forming and sintering (or "firing") phases.

The shape of the bearings must be studied in light of their fragility, particularly in the so-called “green” state, that is, not cooked. In fact, due to this fragility, there are limitations to shapes and sizes for the following reasons:

- a) Effect of stress concentrations particularly on sharp edges

- b) Difficulty in processing (grinding, finishing) before firing

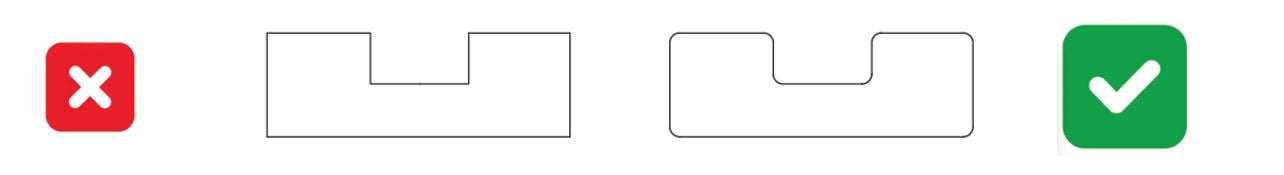

Figure A summarizes the design factors that can affect the manufacturing safety of bearings. In the left column of Figure A, three examples of designs to avoid are described, from above: too small holes, drastic section changes, thicknesses that are too small compared to the general dimensions of the component. The respective measures are listed on the right: from top to bottom, wider holes, softening of section changes, thickening of parts that are too thin compared to the size of the object.

Figure A. Design measures for production safety. From top to bottom: bearing mounting holes, section changes, ring thickness.

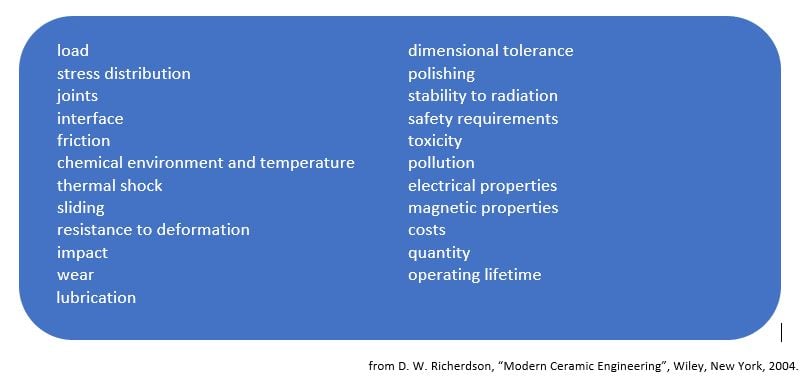

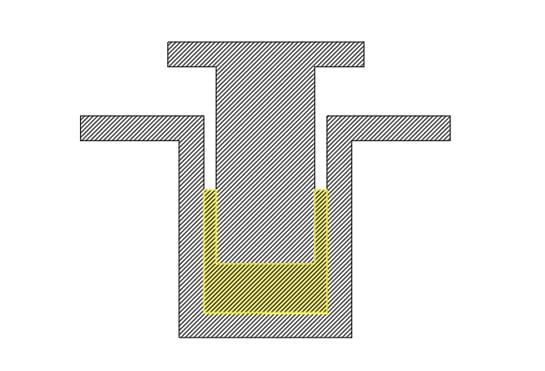

The formed product can undergo, in addition to breakages caused by thermal stresses, also distortions and deformations such as to cause breakage. One of the causes of these deformations is due to the different density that can occur between different points of the same piece, as shown in Figure B. The density of the ceramic material (colored yellow) pressed on the sides can be considerably lower than the density of the material at the bottom, and this could cause deformations during sintering.

Figure B. Possible problem during forming (unidirectional press).

(inspired by R. Morrell, Handbook for the designer, 1985).

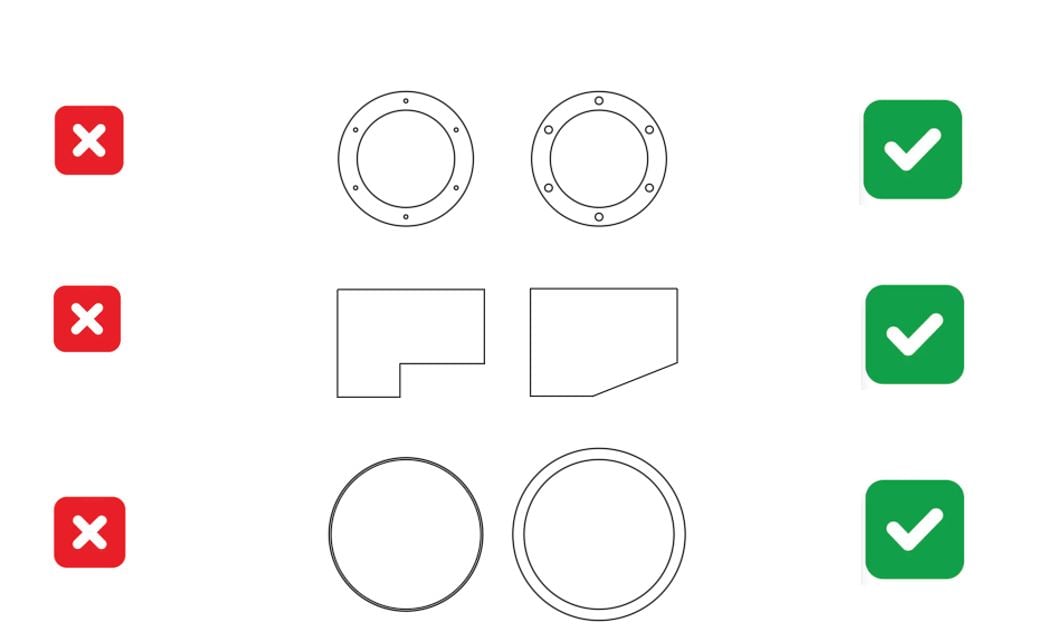

Each ring of the advanced ceramic bearing is normally machined with machine tools to obtain the desired dimensional accuracy, with all the drawbacks associated with mechanical machining, mainly the introduction of defects (see article on "finishing").

On the other hand, although very expensive, it is a necessary operation. However, also in function of this necessity, the shape of the final ring must be drawn following certain, elementary precautions of which Figure A shows an example: sharp edges (on the left of Figure C) are to be avoided because during grinding machining cracks can form. It is preferable, as shown on the right of Figure C, to use chamfers or fillets. In particular, sharp edges, due to their geometry, are more subject to temperature changes than flat surfaces or, in any case, rounded edges.

Figure C. Possible Grinding Problem: Chamfers or fillets (right), when needed are always preferable to sharp edges (left)

Manufacturing information is useful for distinguishing ideal bearings based on the applications and goals you need or want to achieve. Our experts will help you shed some light on your choices.